・What is the size dependence?

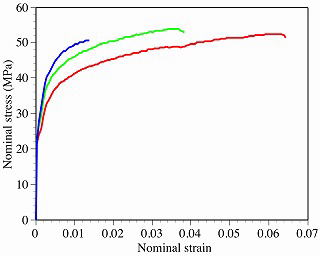

Size dependence is that the mechanical properties of materials vary depending on their

size in the region where the material size is very small. For example,

it is known that a decrease in the thickness causes an increase in the

material strength, as show in Fig.1. Because of the difficulty in experiments,

however, sufficient material testing data to explain this interesting phenomenon

have not been obtained thus far and the major factor in it has not been

clear yet. Therefore, this research is being conducted all over the world.

Fig.1 Tensile test results of aluminum thin foils with thickness 24, 31and 51μm (nominal stress-strain curve)

・ Research contents

In this research, we try to understand the size dependence from both numerical (theoretical) and experimental standpoints. In the

simulation, we introduce some equations expressing these physical phenomena,

namely constitutive equations (strain gradient crystal plasticity theory)

and perform numerical computation using finite element method (FEM). Consequently,

it is possible to obtain detailed information that experiments cannot provide,

such as internal stresses. On the other hand, in the experimental study,

we conduct tensile and bending tests of foils, investigating the variation

in the material properties against the dimension.

Fig.2 Microbending simulation

Fig.3 A bending test of aluminum thin foils with thickness 50μm

・ What can the results of this research be applied to?

Due to the miniaturization of electronic equipment and the development

of MEMS (Micro Electro Mechanical Systems) technology, products with minute

constituents have been increasing recently. In the estimation of their

strengths or lives, as long as the relative load is identical, the conventional

method, which ignores the size dependence of materials, gives the same evaluation regardless of the size of products,

thereby resulting in a wrong estimation of the strengths or lives. If the

mechanism for the size dependence of mechanical properties of materials is elucidated, we can propose constitutive

equations made along the mechanism and can apply them to the simulation-based

design of micromachines in the future.

Research themes

・Crystalline plasticity finite element analyses considering the size dependence of yield strength in metals

・Finite element analyses of ultra fine grained materials using crystal

plasticity models

・Size dependence of yield stress in polycrystalline thin foils under uniaxial tensile conditions

・A study on the size dependence of strength in polycrystalline thin foils subjected to bending

・An experimental study on the size dependence of strength in single crystal thin foils

These research themes are conducted under the support of Grant-in-Aid for Scientific Research (C) in fiscal 2007 and 2008 (the research theme ''Systematization of a micron

scale plasticity theory'').

|